Most customers utilize the bottom of their carts for large purchases to make room for their purchases inside the cart. Items that customers place on the bottom of the basket consist of anything from water bottles to paper towels with an average retail value of $7.00. These items are often missed during the checkout process causing high amounts of shrinkage for grocery stores.

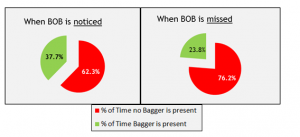

Bottom-of-the-basket (BOB) loss is estimated to cost the U.S. Grocery industry in excess of $2 billion dollars annually. Grocery retailers employ a number of tactics to manage this phenomenon, ranging from operational training initiatives to employing sophisticated tracking technology to limit products from rolling out of the store undetected. Even with the most innovative strategies, the problem persists. TrendSource recently conducted a study consisting of a cross-section of grocery retailers, measuring the impact a bagger has on the BOB detection process (see Figure A).

- When a BOB item is noticed by front end staff, 38% of the time a bagger is present.

- When a BOB item is missed by front end staff, 24% of the time a bagger is present.

Clearly, having a second set of eyes from the bagger has an impact on BOB detection. This may be expected, but grocers don’t always have the resources to staff baggers at all lanes.

Figure A

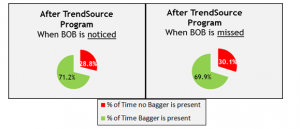

So this begs the question – how do you maximize your resources while preventing products from walking out of the store unnoticed? For a recent client, TrendSource answered that question by partnering to execute an employee reinforcement program combined with a training initiative about best practices to improve BOB detection. The results (see Figure B) showed that the presence of the bagger no longer affected the success in detecting BOB.

Figure B

The process was internalized by all front end staff and they all felt accountable for detection, so baggers could focus on servicing customers and labor costs were affected positively.