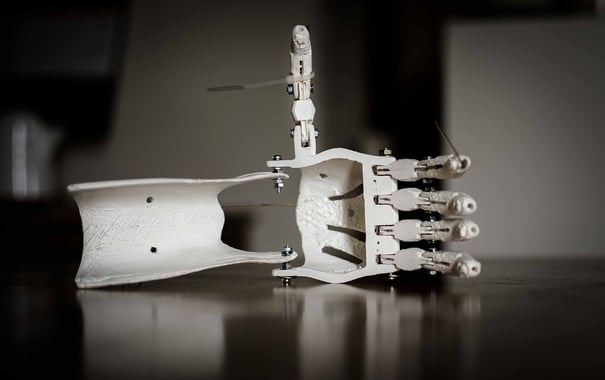

3-D printing is like Augmented Reality—one of those things that nearly everybody has heard about but nobody entirely understands. They understand that it “makes stuff” —really cool stuff like a bionic arm, a Stradivarius violin replica, and human appendages such as ears and even eyes—but aren’t sure exactly how it does so. And few have understood its economic implications, particularly for the world of Consumer Packaged Goods.

That said, 3-Dimensional printing today enjoys a Compound Annual Growth Rate of 31% and will do so through 2020 as more and more companies begin to realize its potential. These printers open exciting possibilities for CPG manufacturers, particularly in the realms of customization, engineering, and packaging.

A 3-D Perspective on 3-D Printing

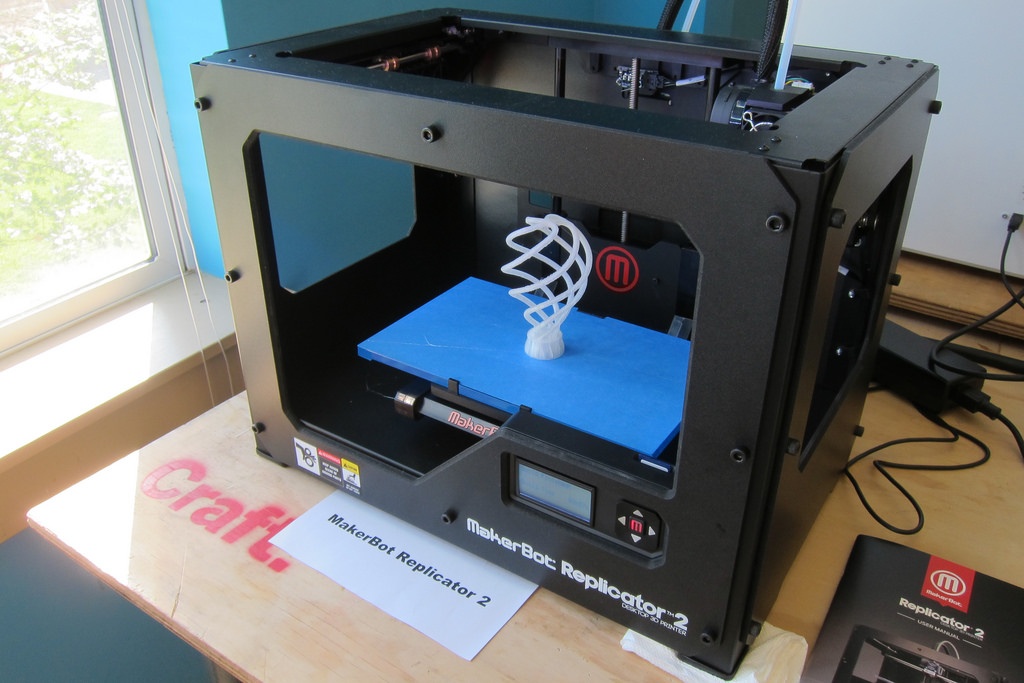

Also, referred to as “additive manufacturing,” 3-D printing is precisely that—the construction of an object through repeated, precise deposits of the building material, literally constructing the item up from nothing. This is the opposite of sculpture, which takes an already formed mass and reduces it into the desired form. And because it is additive construction, items can take shapes previously unthinkable—it is now possible, for example, to construct hollow, single piece items.

Without getting too technical, there are several different forms these printers can take but each essentially accomplishes this same basic function. Some use lasers to harden either a liquid or aerosol building material, others secrete a solidifying substance out of a robotic nozzle.

Like A Million Special Snowflakes

As consumers search for unique identifiers, the era of cookie-cutter conformity and assimilation is gone. Now, customers want personalization in their purchases—they want their manufactured goods to be as unique as they are. Traditionally, such customization would put great strain on manufacturer’s supply chains and prove prohibitively expensive for the manufacturer and customer alike.

Three-dimensional printing stands to change this by allowing manufacturers to produce one-of-a-kind items that do not require an entire reengineering process. That’s perhaps why already 30% of manufacturers are experimenting with the technology and, by 2020 at least 50% will be regularly utilizing it to offer customized and limited edition products.

Some are ahead of the game. New Balance, for example, allows customers to design their own version of their popular 574 shoe, which is then custom “printed” and delivered to them, fitting their foot as perfectly as their personality. Similarly, Barilla Pasta is experimenting with custom designed pasta shapes that restaurants can order, distinguishing themselves with signature pasta shapes and sizes. Both endeavors only seem possible with 3-D printing because the cost, supply chain headache, and engineering would all be insurmountable without it.

A Feat of Engineering

Speaking of engineering, additive manufacturing has also already proven quite useful in the design and testing of new products, allowing engineers to produce multiple design iterations that can each be tested for form, fit, and function. This can be done at a relatively low cost and truly accelerates the time to market; per ExtremeTech, this permits engineers to work through design issues in hours, not days or even weeks.

Package it However You Like

Its versatility and speed also offer enticing implications for the actual packaging of consumer packaged goods. Already, according to Packaging Digest’s recent survey, 1/3 of packaging manufacturers are using the technology today, and 2/3 of those who are not plan to be within the next two years.

As products are discontinued and marketing campaigns shift, packaging regularly needs to be retooled; developing this packaging more quickly and efficiently with 3-D printing streamlines the process. As customization of products themselves increases, so too will similar customization in the packaging that contains it.